Mill Duty Hydraulic Cylinders are designed and manufactured in accordance with ISO 6022 Standard, ensuring superior performance and reliability under heavy-duty operating conditions. These cylinders are built to handle pressures up to 350 Bar, making them ideal for demanding industrial environments.

The robust construction and high-quality materials make these cylinders perfectly suited for continuous operation in steel plants, presses, and other applications requiring long service life, high load capacity, and precision performance.

Available Mountings :

- Front Circular Flange Mounting - MF3

- Rear Circular Flange Mounting - MP4

- Rear Clevis / Pivot Mounting with Spherical Bearing - MP6

- Side Lugs / Foot Mounting - MS2

- Intermediate Trunnion Mounting - MT4

Features :

- Nominal Pressure: 250 Bar

- Piston Diameter: 40 mm to 320 mm

- Piston Rod Diameter: 22 mm to 220 mm

- Mounting Types: 6 Options

- Maximum Stroke Length: 6000 mm

- Maximum Stroke Speed: 0.5 m/s

Hydraulic Cylinder Specifications :

| Bore | Ø B mm |

|---|---|

| Stroke | Up to 1000 mm ±1 mm |

| Rod | Ø mm Hard Chrome Plated, 25 μm Thickness |

| Mounting | Front Circular Flange - MF3 Mounting |

| Working Pressure | 160 Bar |

| Design | Mill Duty, Double Acting |

| Maximum Speed | 0.5 m/sec |

| Test Pressure | 210 Bar |

| Medium | Hydraulic Mineral Oil |

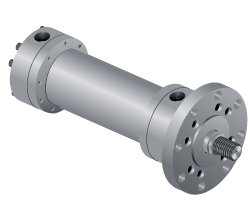

ISO 6022 - Front Circular Flange Mounting - Style MF3

Ordering code

AHP - MD - MF2 - Bore x Rod x Stroke

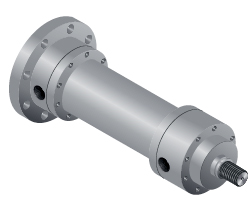

ISO 6022 - Rear Circular Flange Mounting - Style MF4

Ordering code

AHP - MD - MF4 - Bore x Rod x Stroke

ISO 6022 - Rear Pivot Mounted Hydraulic Cylinders with Spherical Bearing - Style MP6

Ordering code

AHP - MD - MP6 - Bore x Rod x Stroke

ISO 6022 - Side Lugs Mounting - Style MS2

Ordering code

AHP - MD - MS2 - Bore x Rod x Stroke

ISO 6022 - Intermediate Trunnion Mounting - Style MT4

Ordering code

AHP - MD - MT4 - Bore x Rod x Stroke