|

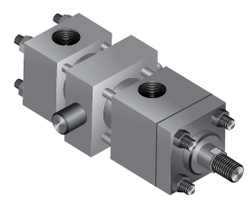

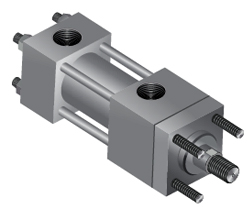

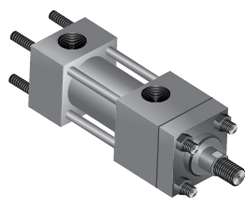

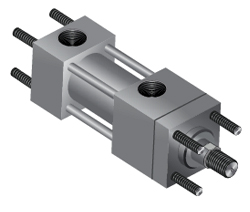

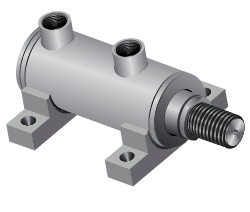

We are a Manufacturer, Exporter & Supplier of Hydraulic Cylinders, Pneumatic Cylinders, Hydraulic Systems, Hydraulic Power Packs, Hydraulic Presses, Hydraulic Filtration Trolleys, Hydraulic Flushing Systems, Hydraulic Test Benches, Special Purpose Machines (SPM), Material Handling Equipment. Majorly we serves our products in Asian, Gulf, Middle East & African Countries.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||